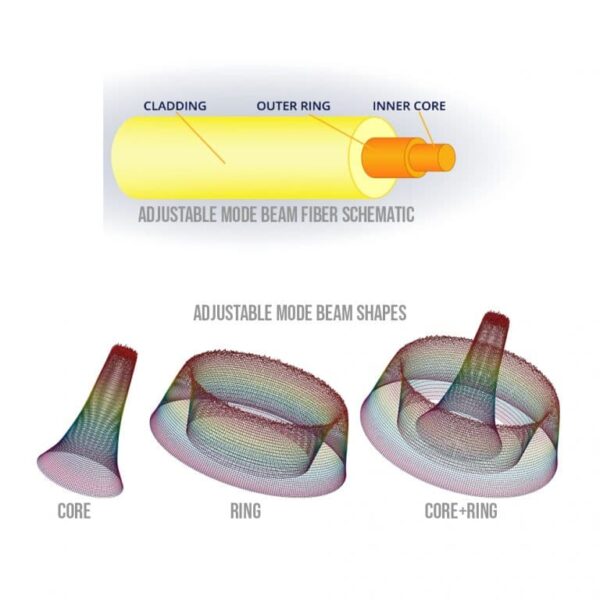

NewScan series 3D remote laser welding scan head adopts the principle of laser scanning deflection to achieve a maximum scanning processing range upto 250*250mm. It can realize wobble welding and other welding process modes such as circular, straight-shaped, Z-shaped, infinite-shaped, 8-shaped, etc., and can quickly import 2D CAD graphics and configure a human-computer interaction interface.

Applications scenarios

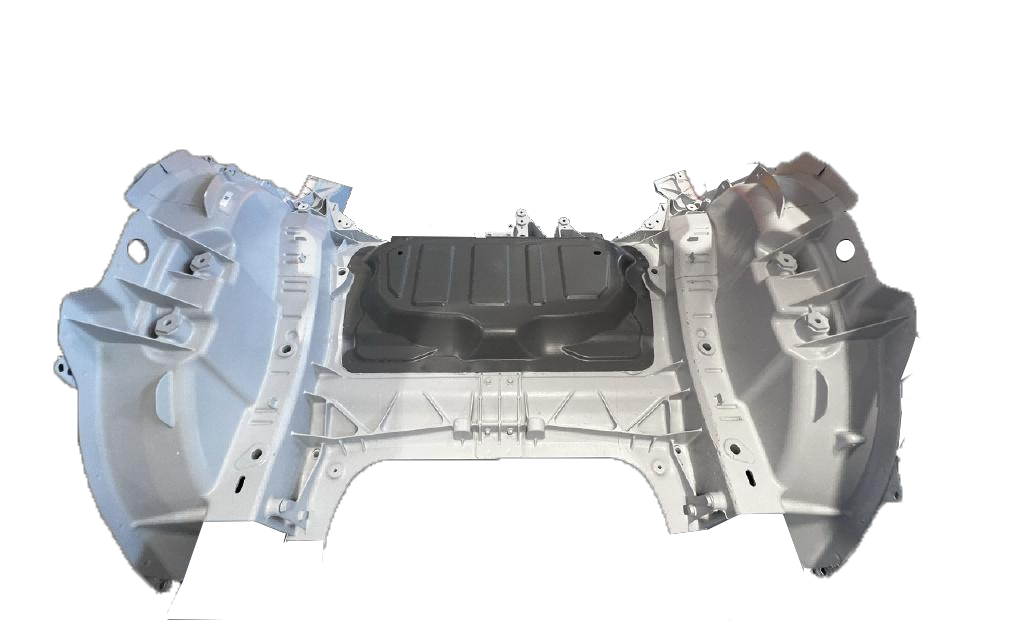

Body-in-white: four doors, side panels, front covers, floor plates, etc

Power battery: explosion-proof valves, poles, sealing nails, adapters, busbar, etc

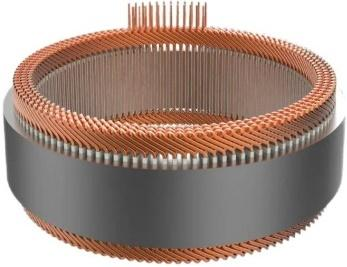

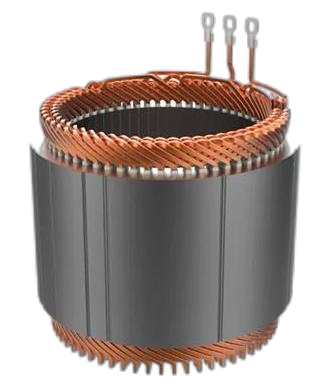

Motor、electric drive: I-Pin/Hair-pin motor, X-pin motor, IGBT drive module, etc

Core Advantages

Flying welding: it can synchronize with the speed of peripheral equipment to realize the flight welding function and improve the welding efficiency;

Offline control: independent control, more stable and reliable system operation;

Various interfaces: with fieldbus, IO, serial port and other outputs; Profinet, Devicenet, Ethernet/IP;

Fool-proof function: with multi-sensor, improve laser safety and reduce human error in industrial production

Main Parameters

| Model: | NewScan-2D/3D |

| Wavelength: | 1030-1090 nm |

| Power: | 6KW/8KW |

| Focus range: | +/-50mm |

| Collimation system: | F100/F125/F150 |

| Focusing system: | F254/F400/F500 |

| Scan range: | 170*100/180*180/250*250 mm |

| Positioning accuracy: | 0.02 mm |

| Interface type: | QBH/QD |

| Fieldbus type: | Profinet、DeviceNet、Ethernet/IP, etc |