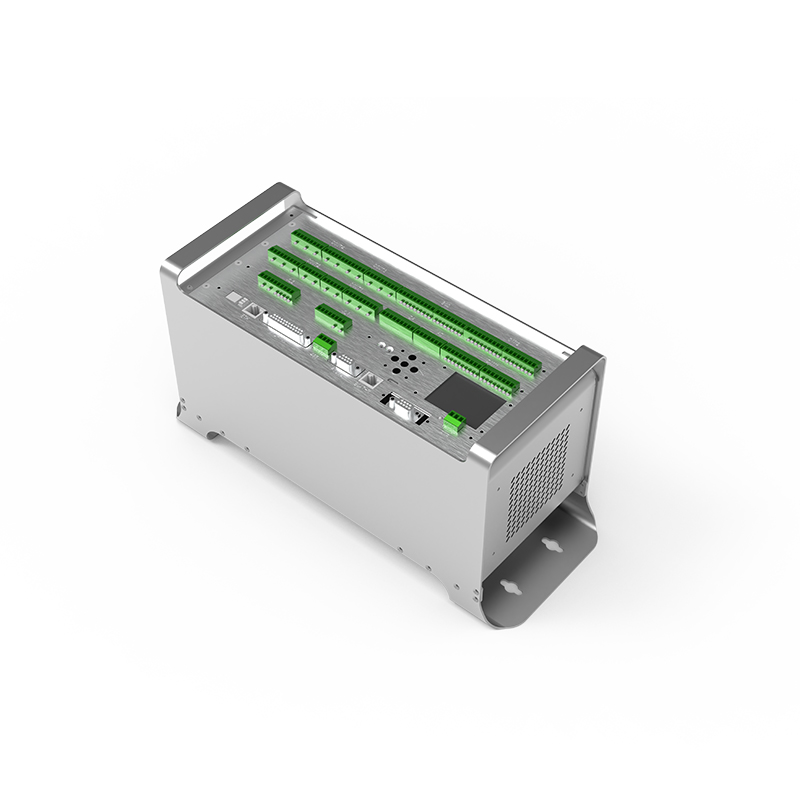

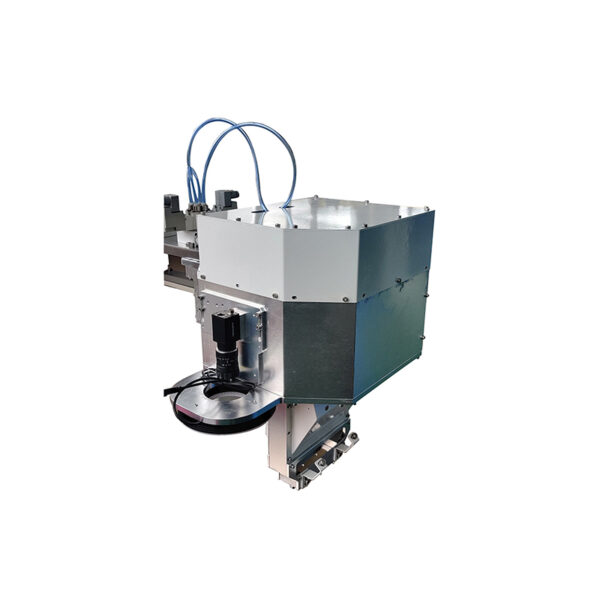

Newlas-AWSI is the central control system for welding heads, welding visual assistance systems, multi-axis linkage systems, machine tools and lasers.

The intelligent welding control system Newlas-AWSI based on bus communication protocol with offline control function and can realize motor control, fast positioning, high repeatability. The control accuracy is up to 0.02 mm. Wobble welding and flying welding can be realized, and the welding seam shape can be customized by software to meet a wide variety of customer application standards.

Feature of Newlas-AIWS welding control system

- Bus communication protocols E-CAT, Profibus, Profinet, Devicenet, Ethernet/IP.

- Robot communication interface, suitable for Kuka, ABB, Fanuc, Motoman and other types of robots.

- Customized welding control, realizing wobble control and flying welding control functions, and wirelessly expanding the welding shape.

- Offline control function.

- Precise control, positioning accuracy 0.02 mm.

- Supports 2D CAD graphics import function.

- Online detection and control before welding.

- Online inspection during and after welding, data analysis and control.

- Laser control and shutter control.

- realize machine tool control and multi-axis linkage control.