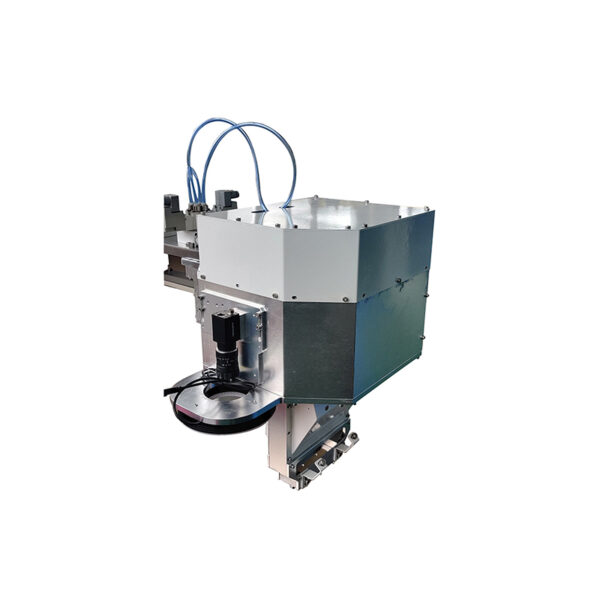

Wobble welding is a double-wedge laser vibration welding method, which is achieved by configuring a special wobble vibration module on the welding head. The swing of the wobble makes the laser weld wider. Even workpieces with large offsets or gaps can achieve efficient and precise laser welding. The NewWobble laser welding head is easy to integrate and can be configured as an integrated device. The external control system only needs to provide the power supply required by the welding head and the control signal connection to complete the construction of the entire welding system.

Application Scenario

Body in white: front hood, four doors, rear cover, side panels

Advantage

- Widened weld (increased tolerance range of welding parts)

- High machining repeatability/process stability

- Better weld formability

- Smoother welded workpiece surface

- Compared with traditional welding heads and galvanometer welding heads, it has a higher overall cost performance

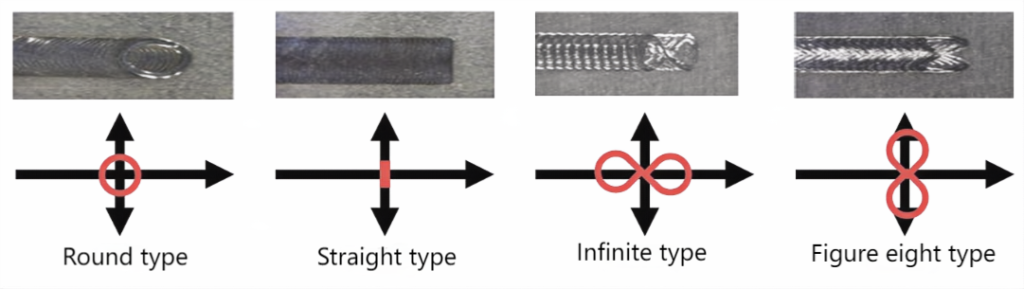

Wobble welding shape

The NewWobble welding head can realize laser stirring of the molten pool. Equipped with the Newwobble control system, it can realize a variety of welding process modes (circular, straight, Z-shaped, infinite, 8-shaped, etc.), meet various process requirements, and have better welding quality.

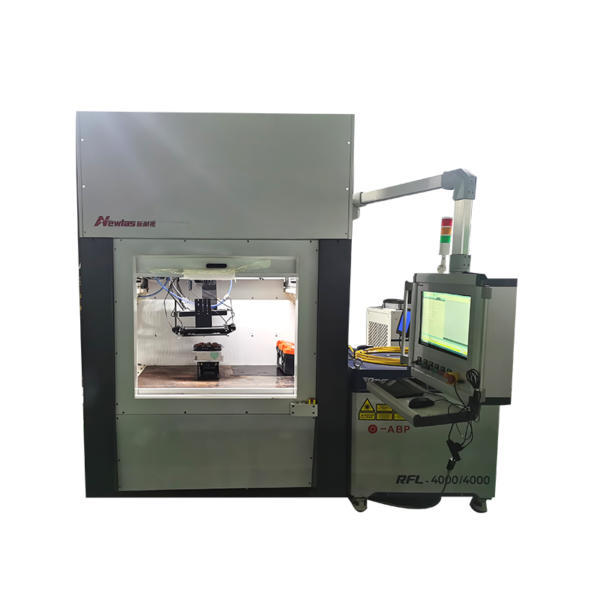

Technical parameter

| Model: | ZW30 | ZW60 |

| Laser wavelength | 1030-1090nm | 1030-1090nm |

| Max laser power | 3kW | 6kW |

| Collimation focal length | 100/85/125mm | 100/150/200mm |

| Focus distance | 200/250/300/400/500mm | 300/600/800/1000mm |

| Swing frequency | 300Hz | 300Hz |

| Maximum swing diameter | Φ5mm-250F | Φ5mm-250F |

| Cooling method | water cooling for head, air cooling for galvanometer | water cooling for head, air cooling for galvanometer |

| Cooling air requirements | Gas cleanliness 0.1um, gas pressure 0.2bar | Gas cleanliness 0.1um, gas pressure 0.2bar |

| Fiber Optic Interface | QBH/QD | QBH/QD |

| Total weight | ≤7kgs | ≤15kgs |

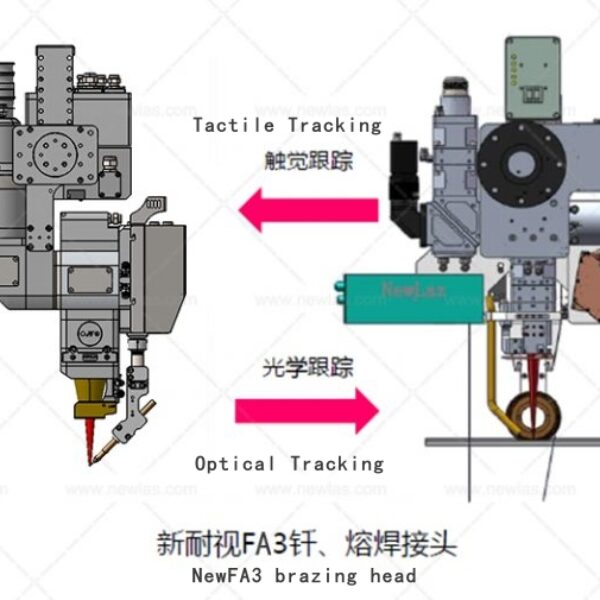

| optional device | Blowing structure( coaxial or side blowing); Weld tracking unit | Blowing structure( coaxial or side blowing); Weld tracking unit |