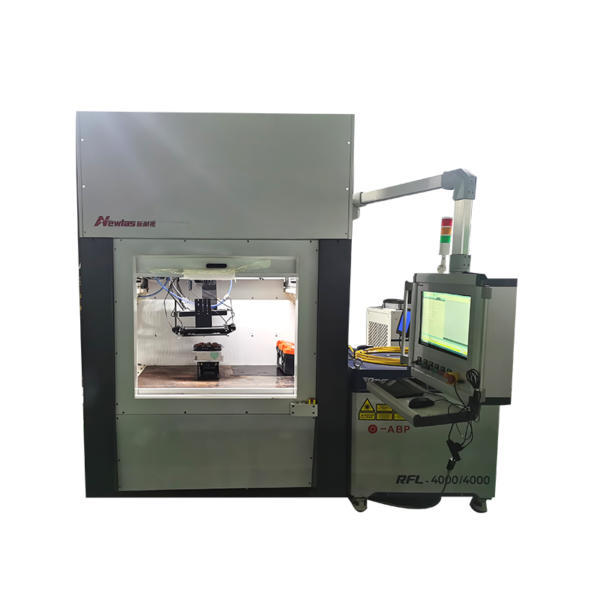

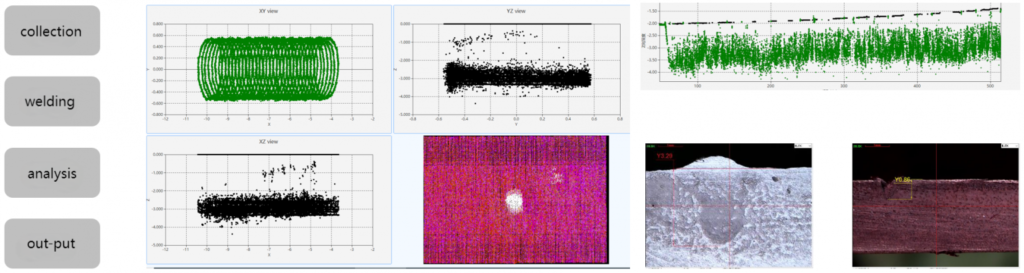

Based on the principle of optical tomography coherent scanning, it is used for laser welding seam tracking, process observation, real-time penetration detection, and real-time quality detection. The coaxial detection laser actively emitted by the OCT scanner is used to scan the front, middle and rear areas of the workpiece welding area in a high-frequency transverse direction, and the OCT sensor is used to simultaneously obtain the three-dimensional welding figure and molten pool penetration depth measurements. High-resolution depth measurement and multi-dimensional visualization, fast and accurate online detection of welding seam position, focus position, welding seam depth and welding seam shaping. In this way, welding faults can be detected and automatically corrected online before welding failure, thereby reducing the scrap rate, testing cost and rework, opening up new possibilities for modern online process monitoring and quality inspection.

Detection of welding process

Advantage

- Pre-welding distance measurement: Use NewOCT to perform pre-welding distance measurement and 3D galvanometer to achieve closed-loop adjustment of focus position for height compensation and improve yield rate;

- In-welding measurement: Obtain welding process penetration data through real-time online penetration measurement to monitor product quality;

- Post-welding inspection: Post-welding morphology inspection can be combined with the production management system to record the motor generation yield and be used for feedback to optimize the welding production process.