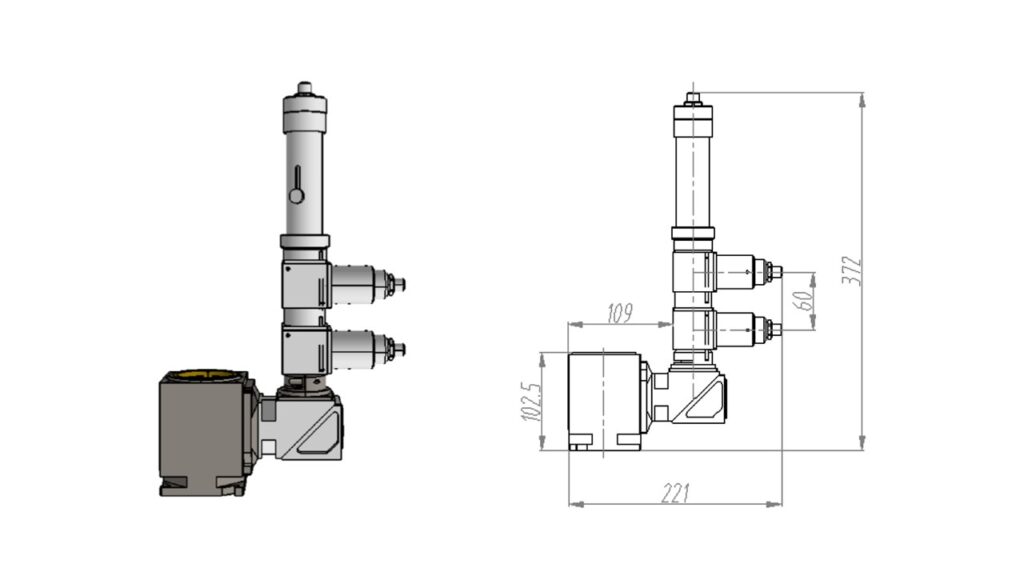

The LWA photoelectric detection system developed by Newlas collects the sound and light signals during the welding process through sound and light sensors, and analyzes the welding process in real time through the independently developed LWA detection software, thereby realizing welding process control in real time.

Features of Newlas LWA welding quality inspection

- Real-time monitoring and analysis of the welding process.

- The sensor is integrated in the welding head to collect multiple photoelectric signals in real time.

- Historical data can be saved according to each product number to trace the processing quality.

| Model | LWA |

| Detector quantity | 3 |

| I/O | 16 input signal,16 output signal |

| Programmable modules quantity | 32/128 |

| Detector acquisition rate | Maximum 40KHZ |

| Number of data channels | Maximum 8PCS |