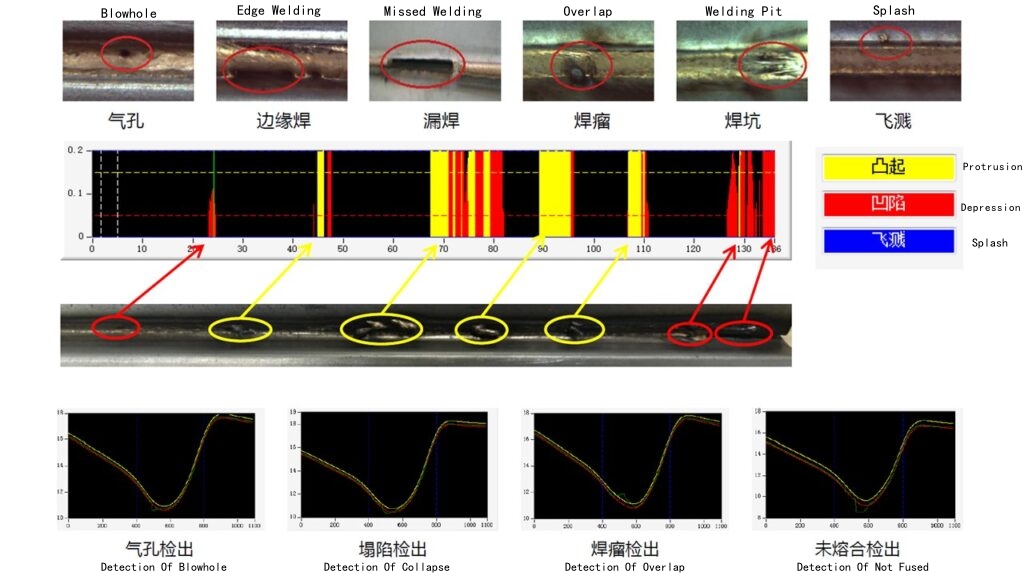

In view of the high appearance quality requirements of laser brazing of car bodies, Newlas has developed a 2D/3D weld seam visual inspection system LBO. This inspection system can effectively identify typical welding defects such as pores, edge welding, leaking welding, nodule pits, spatter, etc. LBO welding quality inspection unit provides real-time dynamic image display and online diagnosis.The defect detection rate of LBO upto 99%.

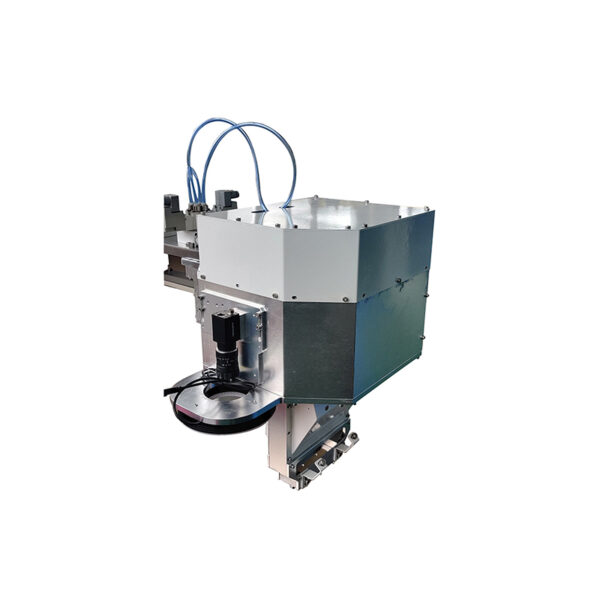

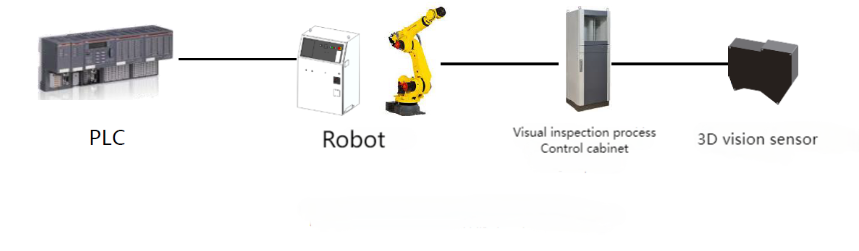

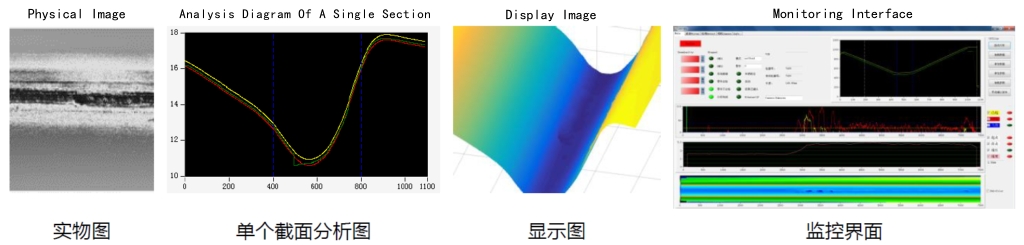

Based on 2D welding detection, the new LBO-3D uses a 3D camera to collect weld data. it can measure the length, width, and depth of the weld seam.

LBO 3D weld measurement and positioning

LBO 3D weld quality inspection

Features of LBO 3D weld visual inspection system

- Efficient and reliable defect identification and detection

- Customized weld geometry measurement

- Weld position change detection

- Online/offline analysis, result visualization

- 2D/3D graphical reproduction of weld details

The unique value of LBO 3D weld visual inspection system

- High-speed detection with a large field of view

- Basis for process optimization

- Online dynamic 2D graphical detection

- Extremely stable weld detection

LBO 3D weld visual inspection system parameters

| Model | LBO-3D |

| Detection speed | 60-100mm/s |

| 3D point velocity | 700,000-1500,000 points/second |

| Maximum detection accuracy(Y axis) | 24μm |

| Horizontal resolution | 19μm |

| Vertical resolution | 1.6μm |

| Laser wavelength | 450nm |

| Laser Class | 2M |

| Interface | 100 Mbit/s |

| Input voltage | 24V DC (ripple less than 15%) |

| Operating temperature | 0-40℃ |

| Weight | <1KG |