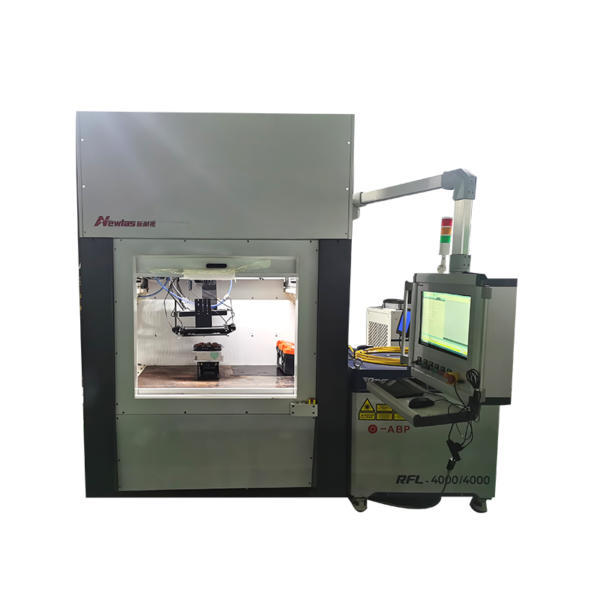

NewScan 3D vision guidance system is an excellent companion for laser processing equipment. For users with high-precision welding requirements, visual guidance and positioning is very important, especially for the welding of EV batteries, EV cells and EV battery packs. Coupled with the use of the Newlas 3D visual guidance system, the quality of the welding process can be significantly improved, which is of great help to the safety and quality of BEV.

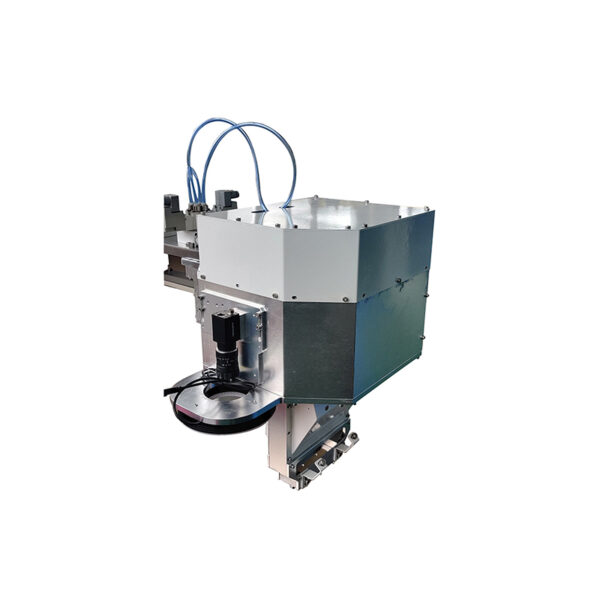

NewScan Vision guidance system can correct the position of the welding workpiece after movement by installing a coaxial camera on the 3D galvanometer. The system uses a self-developed vision algorithm and combines it with hardware to achieve high-precision positioning welding work.

System characteristics

- The identification system is embedded in the welding system, and the identification software is embedded in the welding software to achieve software integration.

- Using advanced image processing algorithms, position recognition can be performed based on the characteristics of different workpieces to ensure the accuracy of the welding position and the stability of the welding effect.

- Provides visual system customization services and can develop visual recognition according to user needs.

system applications

Vision guidance is usually used in situations where workpieces are repeated and a certain degree of welding accuracy is required, such as:

- Welding of EV battery top cover poles.

- Busbar Module welding.

- Square battery top cover welding

- Explosion-proof valve welding

- Hairpin motor welding

Application cases

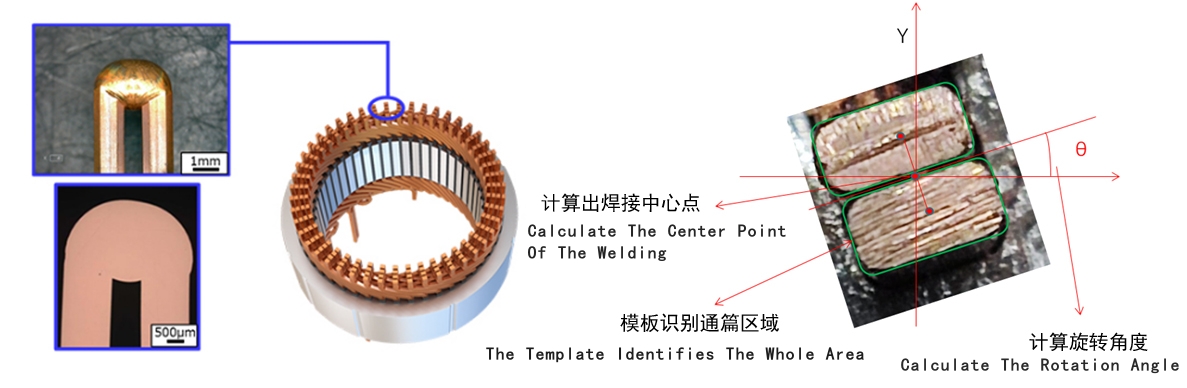

Flat wire motor terminals welding

- Find the coordinates of the welding center point based on the matching template, and calculate the X and Y offsets of the workpiece.

- Calculate the offset angle of the copper sheet based on the straight line parallel to the weld seam, and adjust the mechanical module based on the angle compensation value to weld the copper sheet at the correct angle.