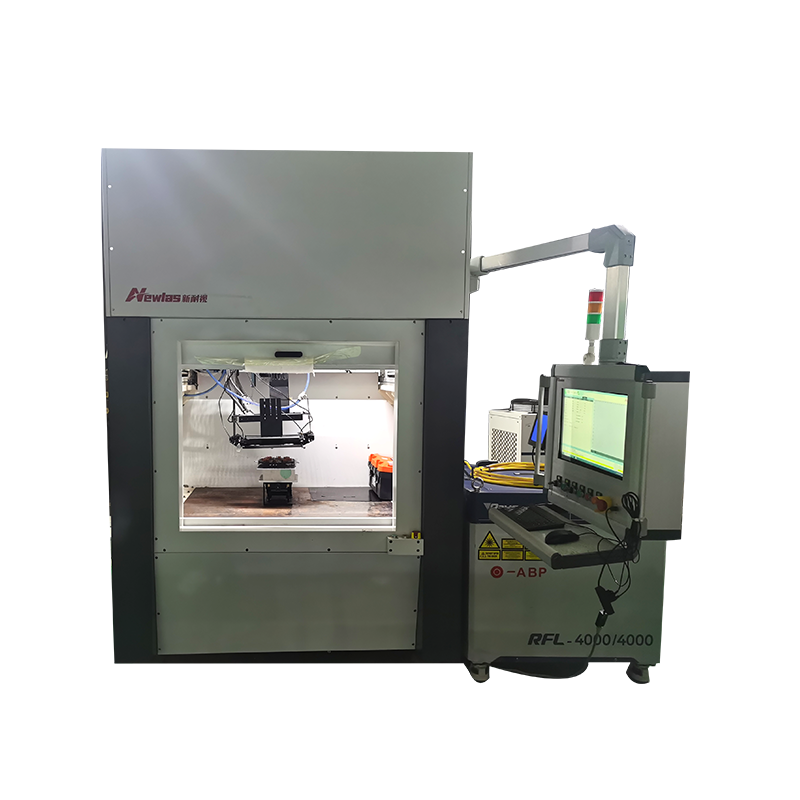

Newlas' flat wire motor X-pin,I-PIN,U-PIN welding product line is committed to providing high-value, high-efficiency, high-quality, and intelligent X-pin,I-PIN,U-PIN laser welding solutions to customers. In view of the difficulties of X-pin,I-PIN,U-PIN welding station, we can provide advanced welding subsystem solutions, covering the operation requirements of the first, middle and last stages of the welding process, and solving the difficulties of X-pin,I-PIN,U-PIN laser welding.

Advantage of newlas

1.Core devices

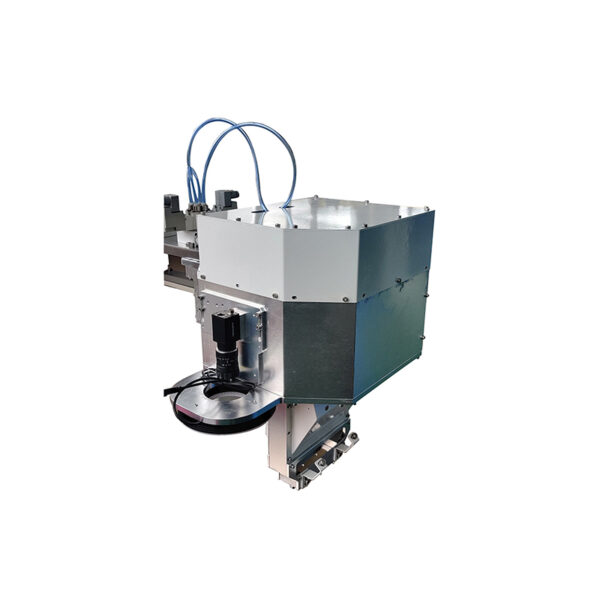

The independently developed 3D galvanometer welding head system 3D-NewScan, the pre-welding visual guidance system NewVisionPos, the welding monitoring system NewOCT, and the post-welding visual inspection system NewVisionMD.

2.Core technologies

The control systems of all core unit devices are independently developed by Newlas and can be perfectly compatible with various functional systems, fully realizing the underlying control interconnection and interoperability, and can also provide users with customized and personalized PIN welding subsystem solutions.

3.Intelligent expert database library

NewPWED, a laser welding process expert library dedicated to X-pin laser welding, has been developed. It has built-in multiple PIN welding process parameter groups to match the different assembly states of the joints to be welded. The corresponding welding process parameter group can be called for welding according to needs to achieve intelligent, High efficiency, high quality welding.

Newlas solutions for X-pin,I-PIN,U-PIN

NewVisionPos pre-welding vision guidance system

1.Accurately identify

3D state of the X-PIN head connection – left and right

Dislocation, front and rear clearance, upper Lower dislocation and angle rotation;

2.Accurately identify X-pin connector status,X resolution<

0.08mm, Z resolution<

0.015mm.

NewOCT in-welding monitoring system

1.Strong anti-interference ability, not subject to welding Smoke and other factors during the welding process;

2.Sampling frequency 100kHz;

3.Axial resolution (penetration accuracy)<0.02mm;

4.The maximum detectable range of penetration depth is up to

10mm, meets the biggest welding

depth requirements.

NewVisionMD post-weld visual inspection system

1.Can detect abnormal solder joint size,Abnormal position, splash defects and other key factors;

2.Efficient and reliable defect detection,1280 points/contour-million images Pixel resolution, X-direction points Resolution <0.15mm, Z direction Resolution<0.04mm