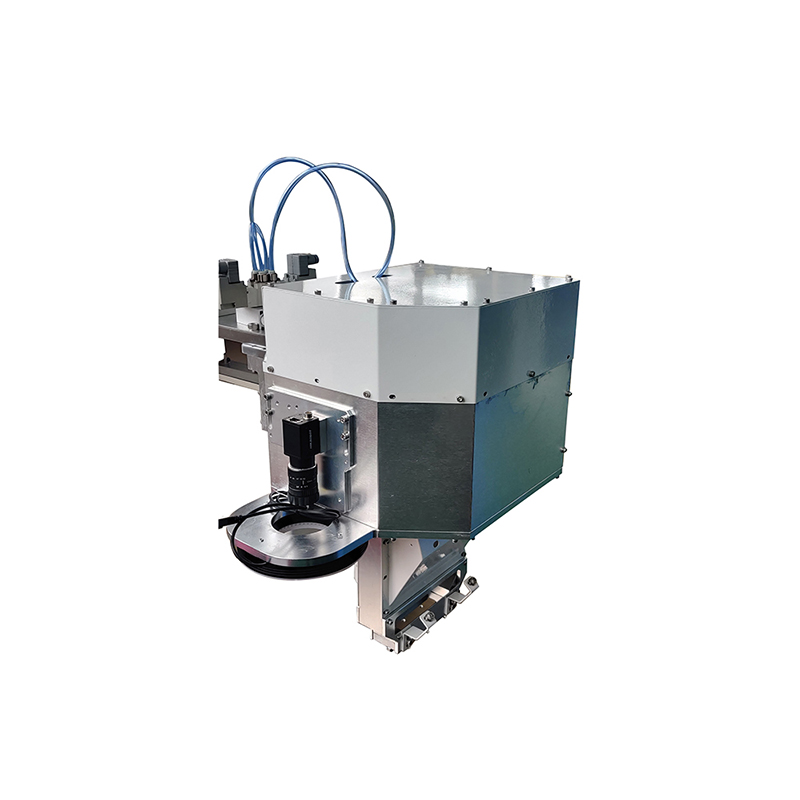

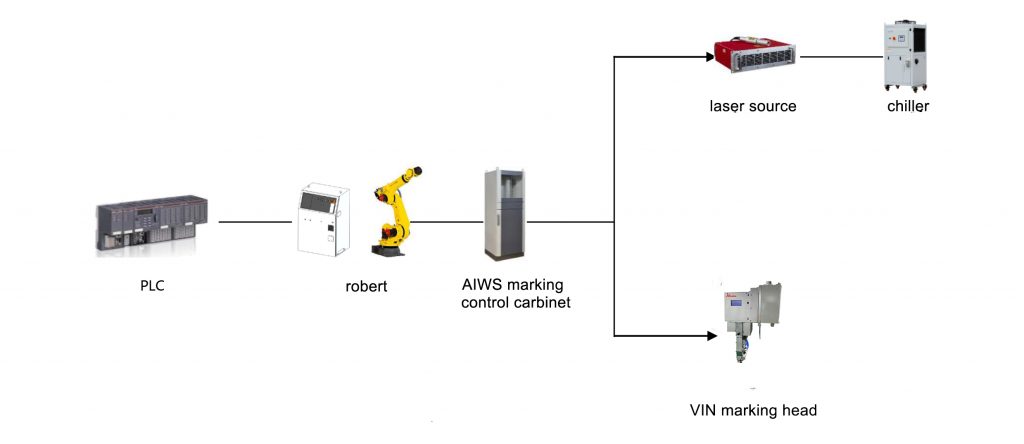

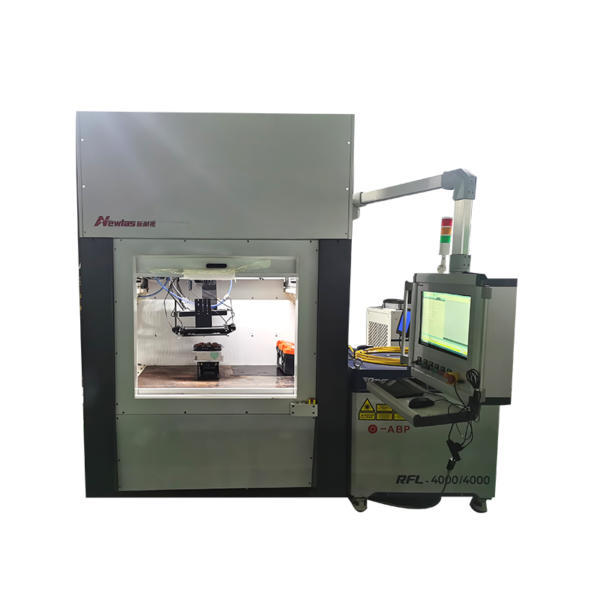

NewMarking, Newlas has customized a comprehensive and highly adaptable laser VIN marking system to cope with all situations and applications. It can achieve clear coding, non-contact coding, high efficiency, and can be configured with a visual inspection system. Realize the integrated functions of engraving and detection. This product can share for multiple vehicle models, reducing customer site occupation. It also solves the problem of high-strength steel that cannot be carved using traditional scoring processes.

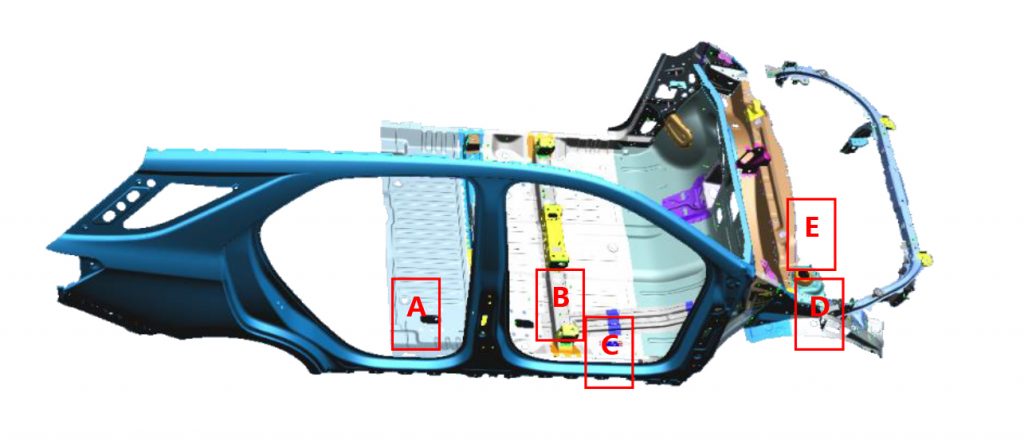

Common Marking Locations

The Newlas laser VIN coding system uses a laser and galvanometer system to engrave the VIN code on the vehicle body. The width and depth of the characters meet the requirements of the OEM standard and relevant regulations. The laser VIN coding system can replace the traditional mechanical coding system. The non-contact coding system has high efficiency and good passability. It can be coded at multiple positions on the car body and can be shared by multiple vehicle models.

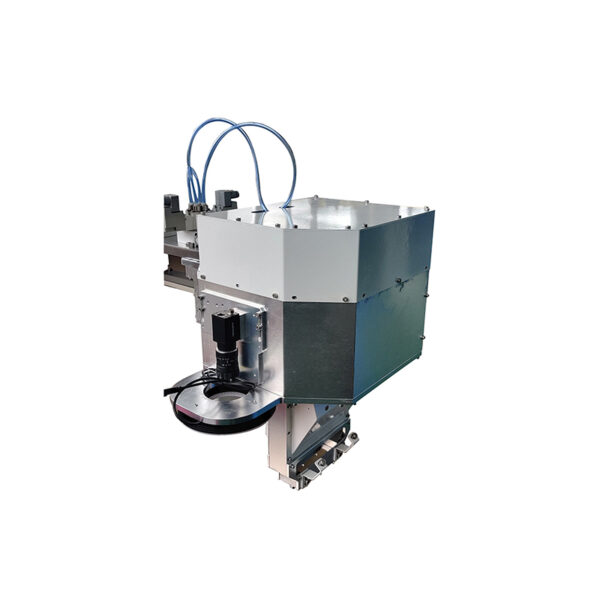

Functions of Newlas laser VIN coding system

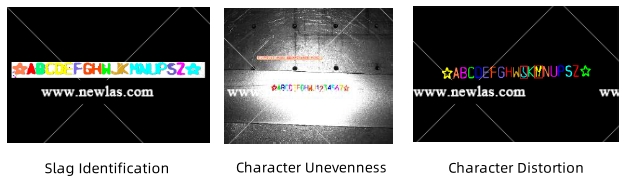

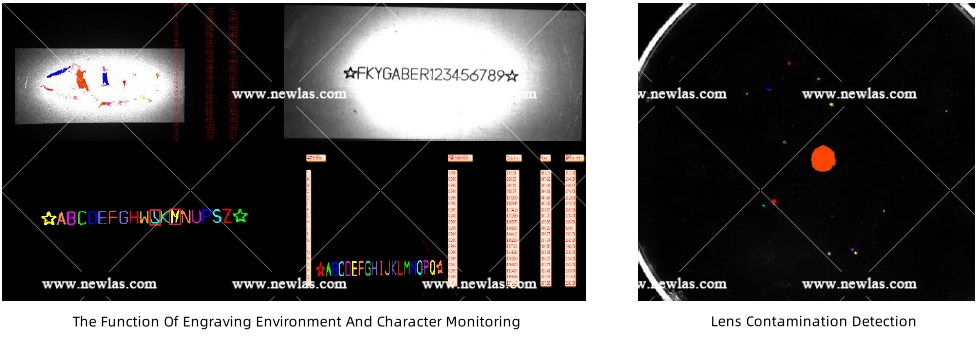

- Visual detection function, status output feedback, can detect whether there is slag and whether the characters meet the standards

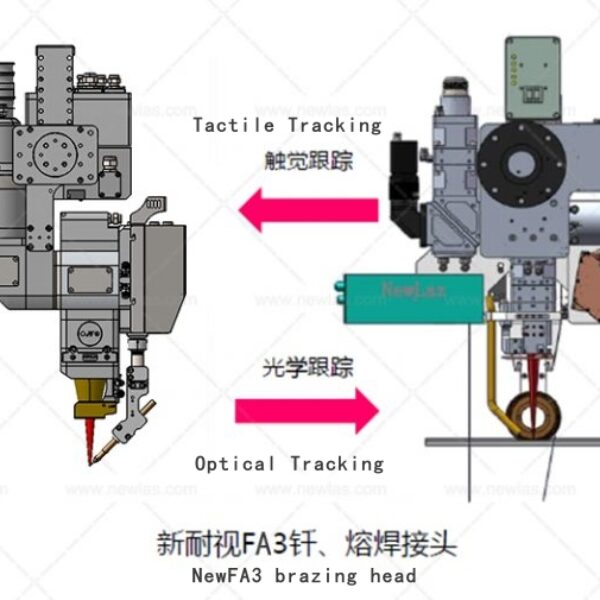

- Adaptive function ensures reliable contact between the dock and the body surface

- Anti-splash protection function

- Water cooling system, reliable performance

- Protective lenses are easy to replace

- Protection lens stain detection function

- Highly integrated with built-in process dust removal

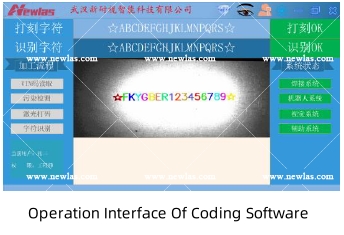

- Customized software development with manual VIN code input function

Laser VIN coding system features

- Non-contact coding, highly adaptable and can reach any angle of the component

- Multiple models can share the docking station, with flexible location and no need to change tools.

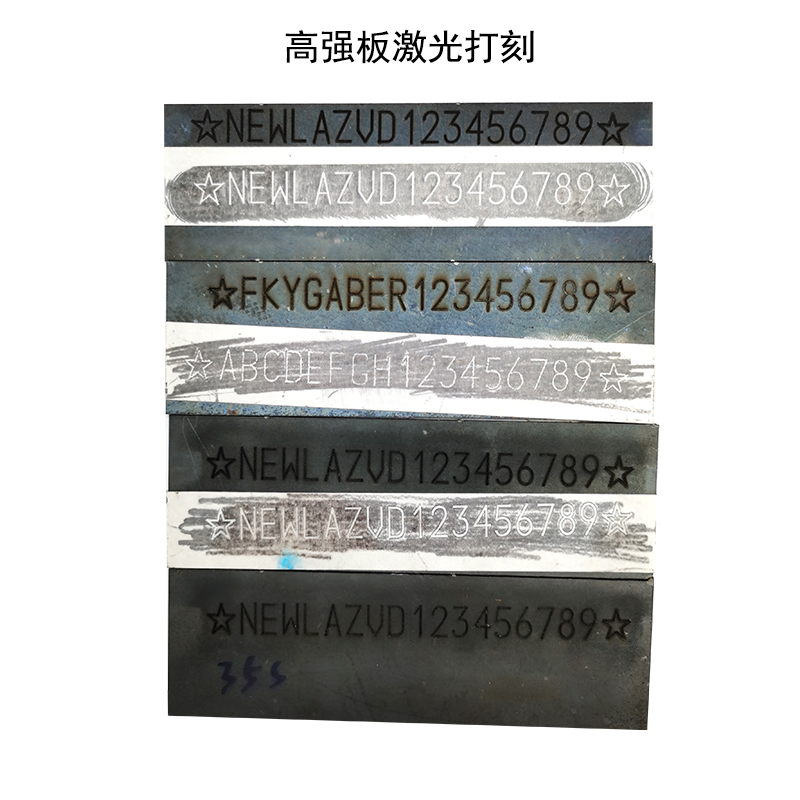

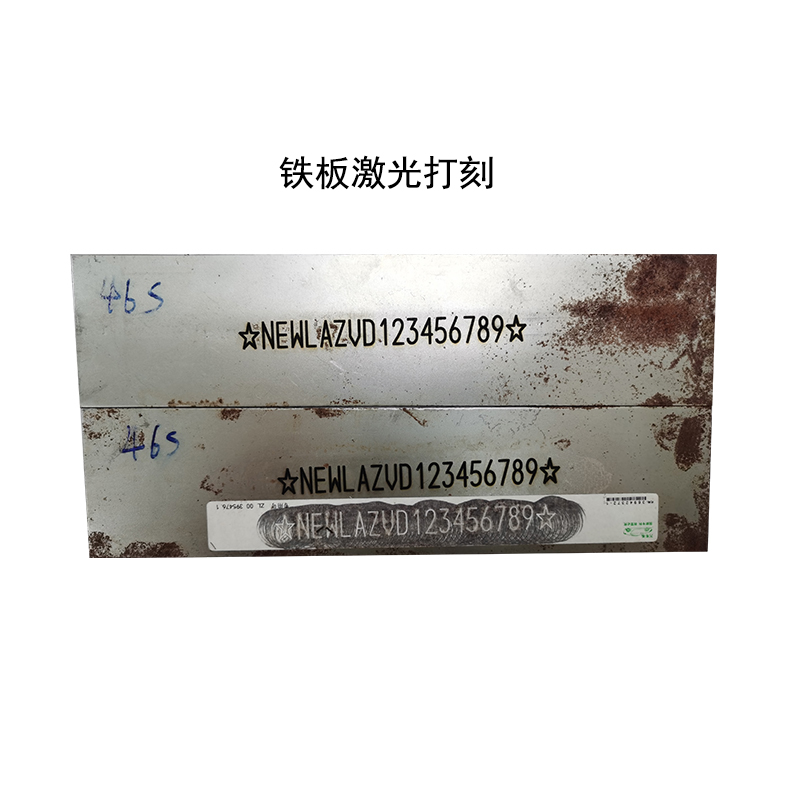

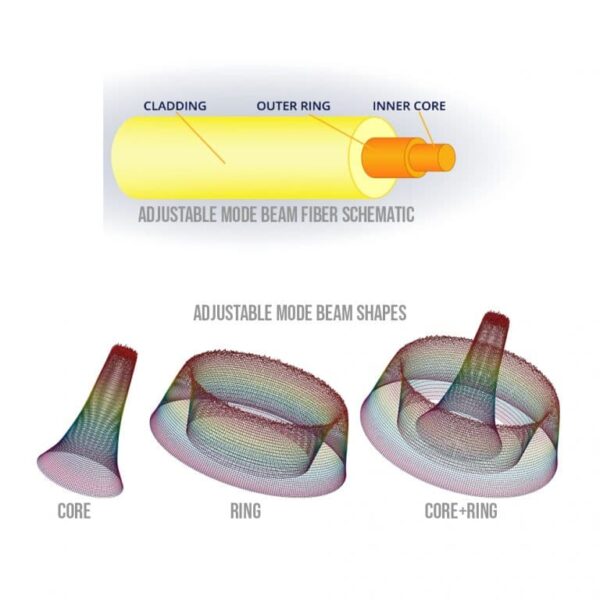

- Coding can be achieved with different thicknesses and different materials

- Coding speed is fast, with in 20s

Laser VIN Coding System Parameters

- The height of the engraved characters is 8mm and the width is 15mm, which can be adjusted according to requirements.

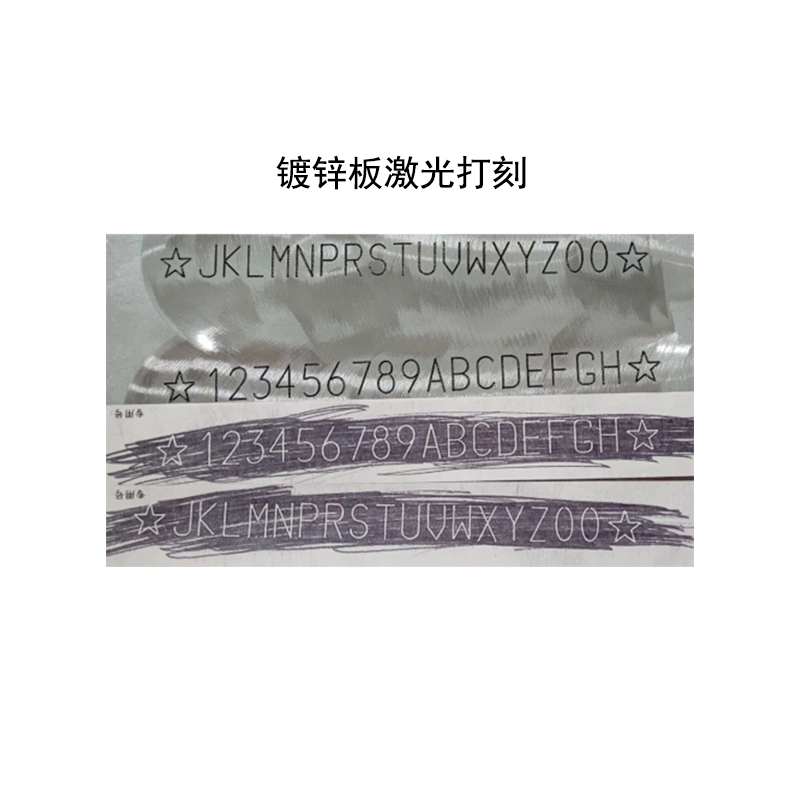

- The engraving depth is 0.25mm and the width is 0.5-0.7mm, which complies with the national standards for characters.

- High engraving efficiency, it only takes 20 seconds to engrave 19 characters by pressing hard

- It can realize the VIN coding process on 0.65mm thin plate parts;

| Model | NLM-300 | NLM-500 |

| Galvanometer | NL-FC75-F210 | NL-FC75-F210 |

| positioning accuracy | 0.02mm | 0.02mm |

| Graphic import | support | support |

| Detection function | Optional | Optional |

| Communication Interface | E-CAT, Profibus, Profinet, Devicenet, Ethernet/IP | E-CAT, Profibus, Profinet, Devicenet, Ethernet/IP |

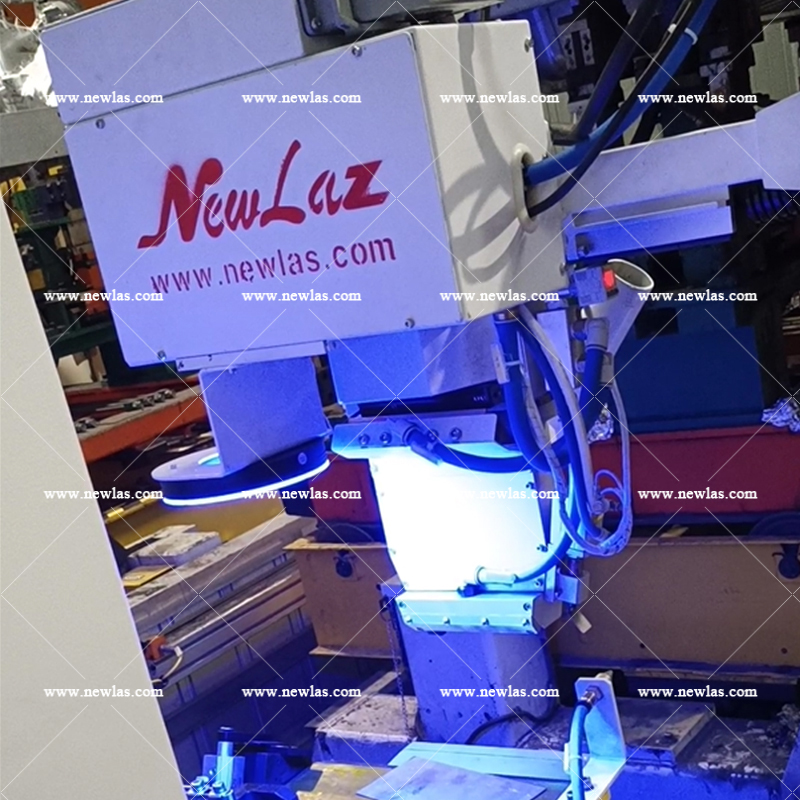

Customer cases

Customer requirements:

An OEM factory in Wuhan has four vehicle models on the same line and uses laser to print VIN codes;

The VIN coding depth of the body-in-white is >0.2mm, and the body production line cycle time is 65JPH (42s). After coding is completed, a visual system is used to identify and record the coding content; in compliance with national standards, it is necessary to ensure that the rubbing is clear after spraying;

Laser VIN code coding solution:

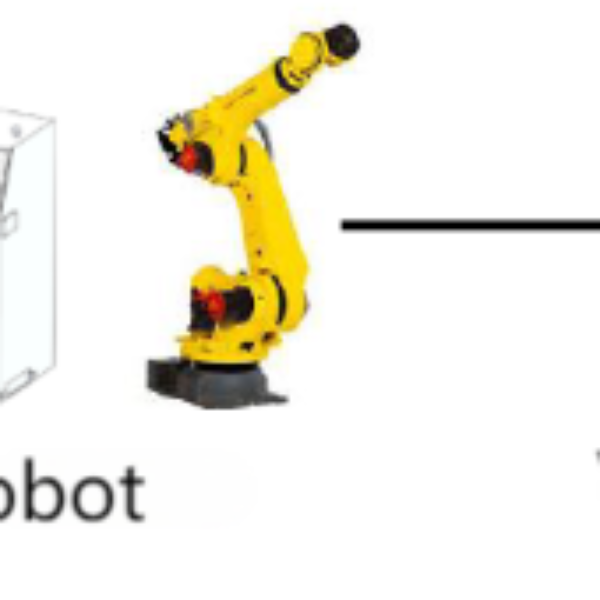

Newlas provides a complete set of robotic laser VIN code marking solutions, including robots, laser coding systems, inspection vision systems,while also providing simulation verification of vehicle accessibility.