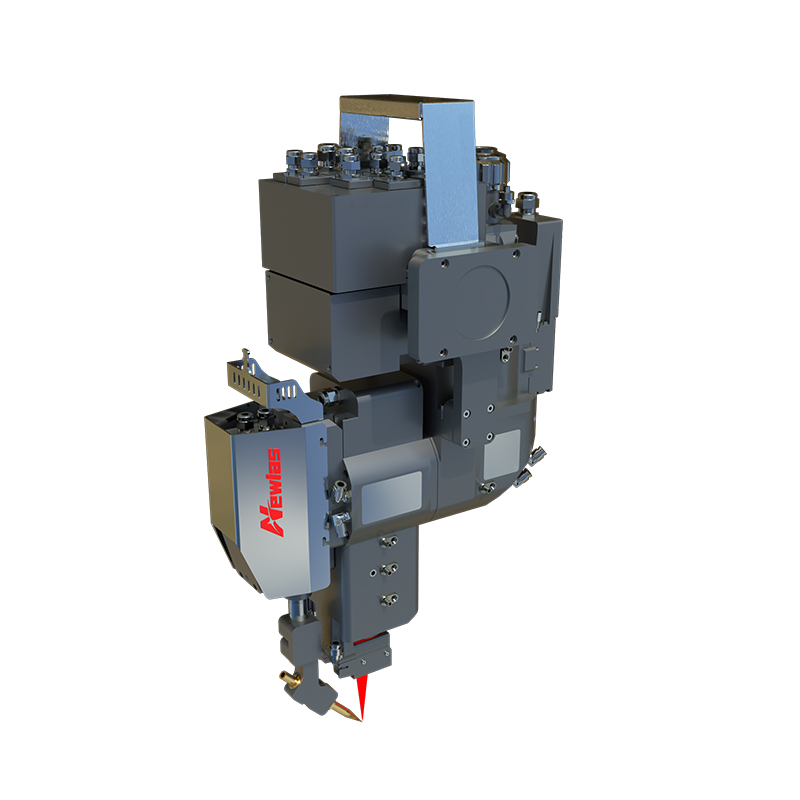

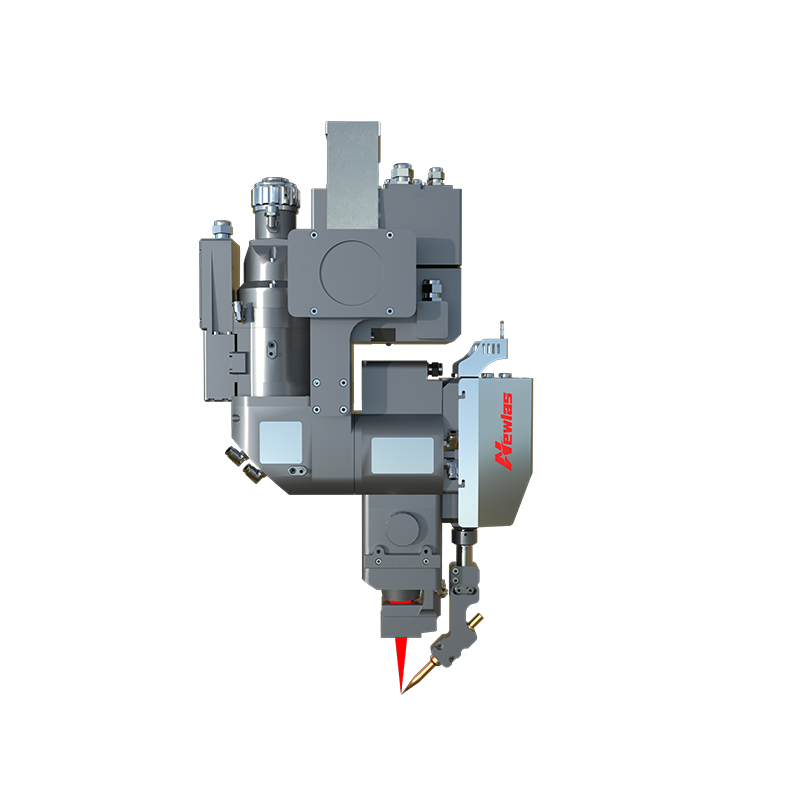

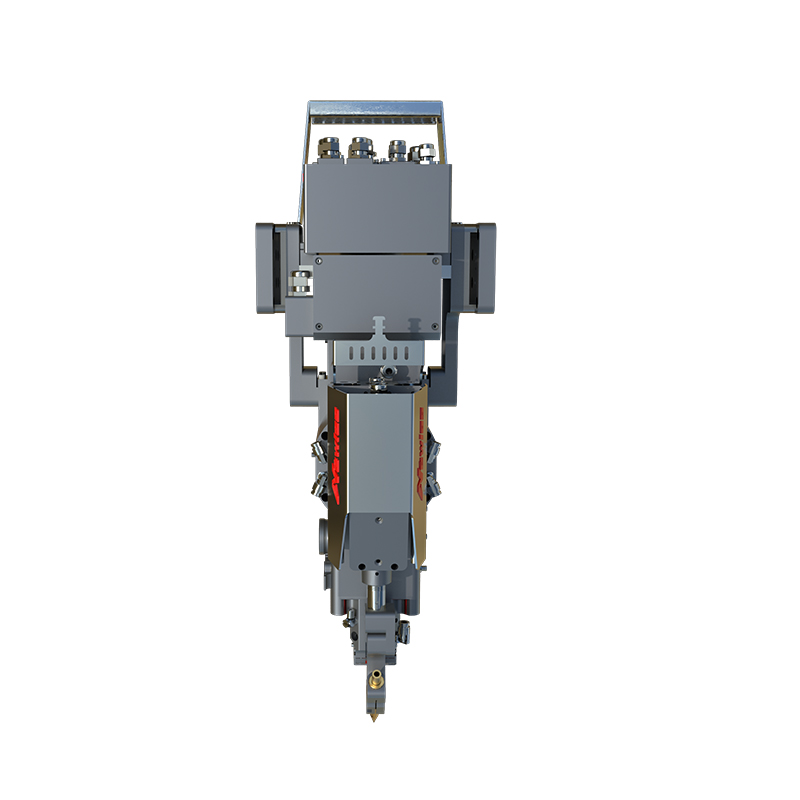

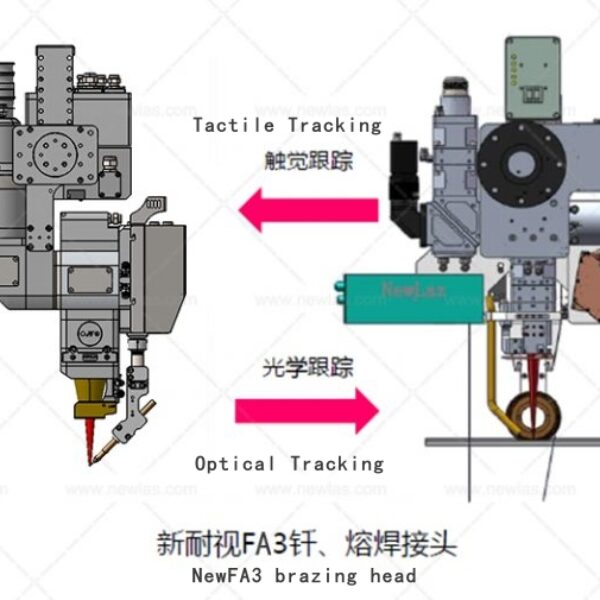

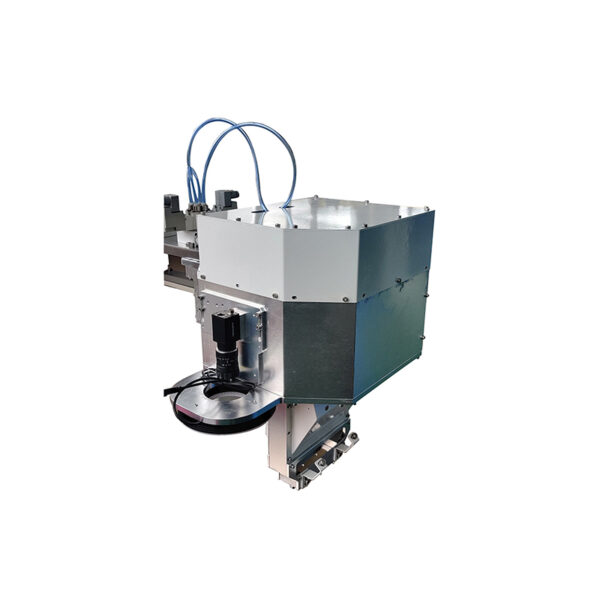

The NewFA3 brazing and filler wire welding head is equipped with high-precision tactile seam tracking and automatic focal length compensation function to accurately control the process laser to achieve unmatched welding quality.The tip of the filler wire precisely detects the weld edge and safely guides the joining process along the seam. At the same time, the focused light spot always follows the tip of the filler wire.

Applicable scene

Body in white: roof, rear cover,front cover,longitudinal beam parts welding

EV battery: welding for EV battery packs, end&side panels, chassis of battery packs, battery trays, water cooling plates,etc.

Core advantages

Welding wire guide tracking: the welding wire tactile sensor accurately controls the tracking force, automatically compensates for the deviation of the part, and realizes the stability of the welding process;

Automatic focusing: the welding wire can follow the seam up and down, and the focus is automatically adjusted to ensure that the spot size on the welding wire is constant;

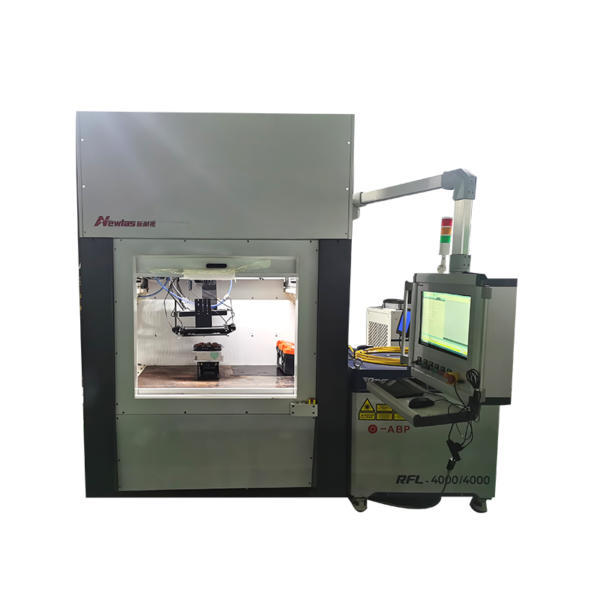

Easy integration: fast integration with external systems such as wire feeding systems, lasers source, camera displays;

Modular design: at the same time, NewFA3 brazing head have functional ductility, suitable for any type of laser source, and easy to maintain and expand;

User-friendly: it can be seamlessly replaced with equipment from European and American area, and is compatible with existing laser brazing and fusion welding systems, with short debugging cycle and strong stability.

Main parameters

| Model: | NewFA3 |

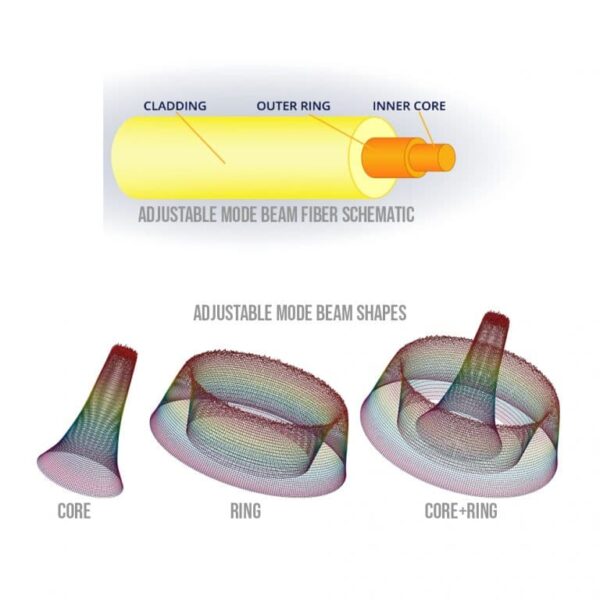

| Fiber optic interface: | QBH/QD |

| Wavelength: | 1030-1090nm |

| Max power: | 8kw |

| Swing range: | ±90 |

| Unidirectional adjustment range of focus module: | 0-3mm |

| Adjustment range of telescopic arm: | ±5mm |

| Cooling method: | Water cooling |

| Power supply: | 24V/10A |

| IP degree: | IP64 |