-

LS Multi-channel optical gate

The LS series multi-channel optical gate can expand the laser optical path and has a coupling efficiency of 99%. At the same time, it is equipped with a laser monitoring system, which can effectively monitor the status of the laser. It adopts external alarm customization and can be controlled by master and slave, realizing one machine with multiple functions.

Read More -

Newlas car body VIN Laser Notching head

The laser notching system developed by Newlas is equipped with an intelligent control system, with adaptive adjustment function and character image detection function, which can meet the notching processing range of 150*150mm.

Read More -

LBO-3D quality inspection of pre & post welding

LBO-3D uses 3D cameras and visual algorithms to detect the appearance quality of seam welding. It can effectively identify typical welding defects such as porosity, edge welding, leaking welding, weld nodules, weld pits, spatter, etc., and provide real-time dynamic image display and online diagnosis.

Read More -

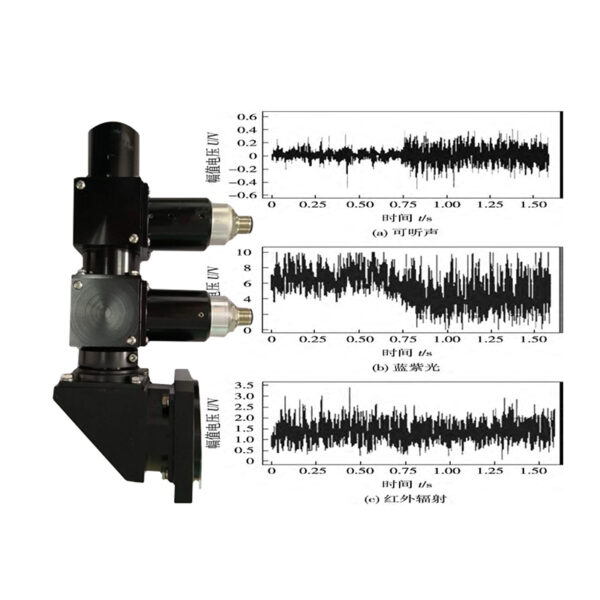

Newlas Welding process quality inspection unit

The LWA photoelectric detection system developed by Newlas collects the sound and light signals during the welding process through sound and light sensors, and analyzes the welding process in real time through the independently developed LWA detection software, thereby realizing welding process control in real time.

Read More -

New-Wobble single side laser welding head

The NewWobble welding head can realize laser stirring of the molten pool. Equipped with the Newwobble control system, it can realize a variety of welding process modes (circular, straight, Z-shaped, infinite, 8-shaped, etc.), meeting various process requirements and having better welding quality.

Read More -

New-OCT Optical Coherence Tomography for laser welding

New OCT is used for laser welding seam tracking, process observation, real-time penetration detection, and real-time quality detection.

Read More -

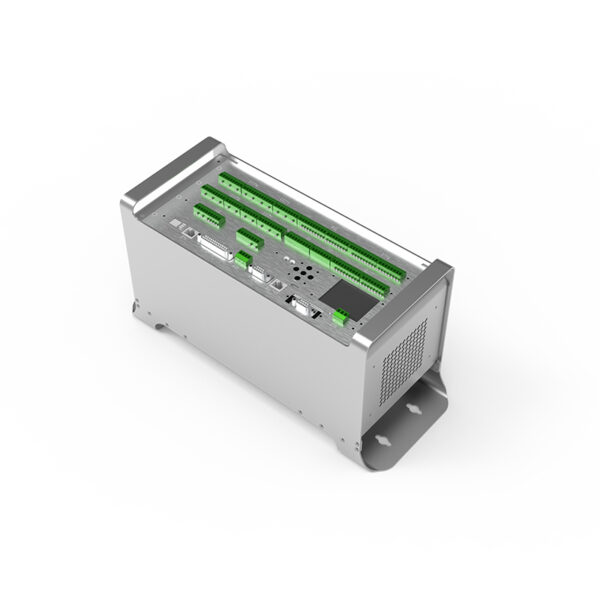

Newlas-AIWS welding control system

Newlas-AWSI is the central control system for welding heads, welding visual assistance systems, multi-axis linkage systems, machine tools and lasers.

Read More

The intelligent welding control system Newlas-AWSI based on bus communication protocol with offline control function and can realize motor control, fast positioning, high repeatability. The control accuracy is up to 0.02 mm. Wobble welding and flying welding can be realized, and the welding seam shape can be customized by software to meet a wide variety of customer application standards. -

NewScan-2D/3D Remote Laser Welding Head on the fly

Newlas's 3D/2D remote laser welding scan head, specially designed for robot/CNC-assisted welding tasks.

Read More

While a robot guides the scan system along a part’s contour, with the help of the Newlas vision systems,Newlas 3D/2D remote laser welding head quickly and accurately deflects and fine-positions the welding spot. WeldAssist units eliminates the need for complex robot motions, reducing weld-to-weld positioning time to mere milliseconds. It's compact design allows easy mounting on industrial robots. Its optics optimized for fiber-coupled disk or fiber lasers up to 8KW. -

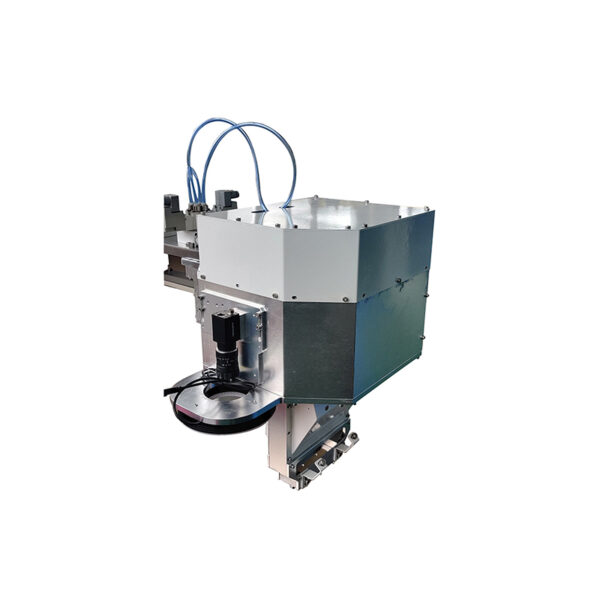

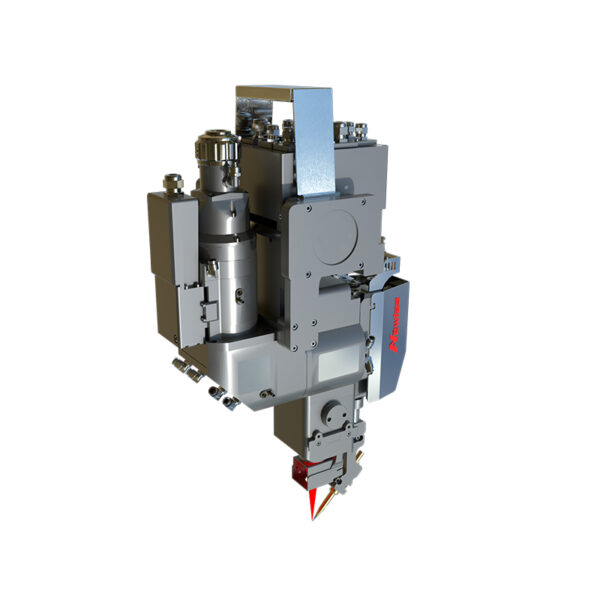

The NewFA3 brazing and filler wire welding head

The NewFA3 brazing and fill wire welding head is equipped with high-precision tactile seam tracking and automatic focal length compensation, which is suitable for high-quality and high-efficiency welding of key components in automotive vehicles such as body in white, battery electric vehicle , hire pin motors, electric drives, etc.

Read More