-

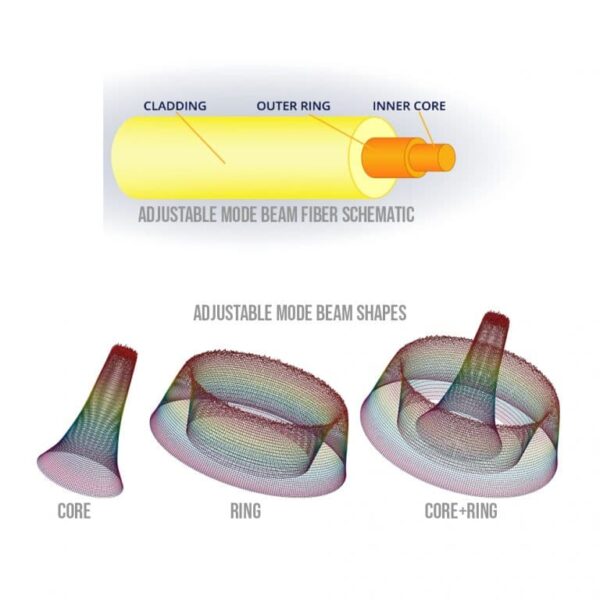

Adjustable mode beam scanning welding control system

Read More -

Body-in-white laser VIN coding system

The Newlas laser VIN coding system uses a laser and galvanometer system to engrave the VIN code on the vehicle body. The width and depth of the characters meet the requirements of the OEM standard and relevant regulations. The laser VIN coding system can replace the traditional mechanical coding system. The non-contact coding system has high efficiency and good passability. It can be coded at multiple positions on the car body and can be shared by multiple vehicle models.

Read More -

Intelligent remote laser welding system on the fly

The hardware of the NewScan 3D Pro remote welding system has been fully upgraded. It is specially designed for the electric vehicle battery industry. It comes with a number of sensing detection technologies and a large welding process library, which can meet a variety of processing application scenarios, including busbar, tabs, and shells of electric vehicle battery and flat wire motor X-PIN,I-PIN welding.

Read More -

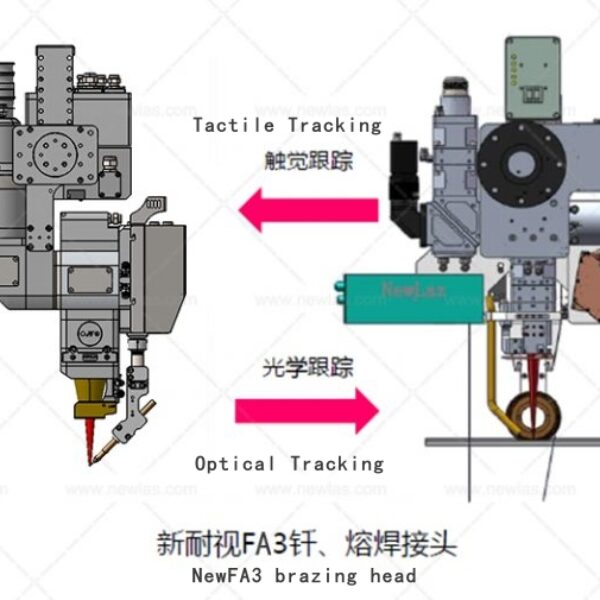

The laser brazing and filler wire welding system

Body-in-white laser brazing is mainly used for car roof,luggage trunk cover,flow channel , chassis welding.The Newlas brazing welding system is equipped with a tactile tracking system and an optical tracking system, which can accurately track the position of the welding seam and ensure welding quality.

Read More -

laser welding subsystem for flat wire motor X-PIN,I-PIN,U-PIN

Newlas' flat wire motor X-pin welding product line is committed to providing high-value, high-efficiency, high-quality, and intelligent X-pin laser welding solutions to customers. In view of the difficulties of X-pin welding station, we can provide advanced welding subsystem solutions, covering the operation requirements of the first, middle and last stages of the welding process, and solving the difficulties of X-PIN laser welding.

Read More -

NewScan 3D vision guidance system before welding

NewScan Vision guidance system can correct the position of the welding workpiece after movement by installing a coaxial camera on the 3D galvanometer. The system uses a self-developed vision algorithm and combines it with hardware to achieve high-precision positioning welding work.

Read More -

NewLBO-3D post-weld quality visual inspection system

The NewLBO-3D post-weld quality visual inspection system is widely used for inspection of fillet welds, V-shaped welds, tailor-made welds, etc. It can effectively identify typical welding defects such as pores, edge welds, missing welds, weld nodules, weld pits, spatter, etc., and provides real-time Dynamic image display and online diagnosis. The quality of welds is monitored and saved in real time to achieve product traceability.

Read More