In the field of manufacturing, especially in the EV battery welding industry, achieving consistent and high-quality results can be a challenge. This is particularly true when it comes to fly welding, a process that requires precise control and intricate calculations at high speeds. Add to that the complexity of ensuring accuracy during acceleration and deceleration, and the task becomes even more daunting.

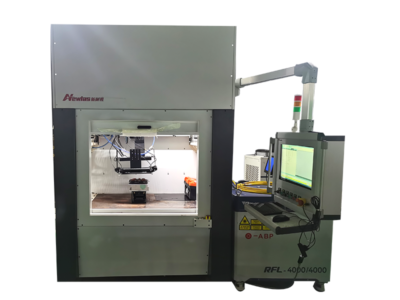

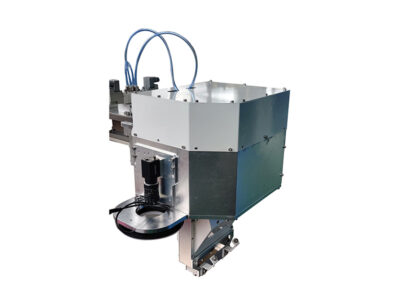

Cylindrical battery fly welding module

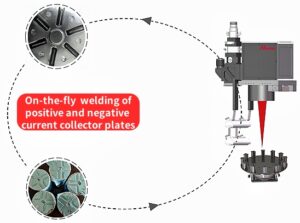

Cylindrical battery positive and negative poles fly welding

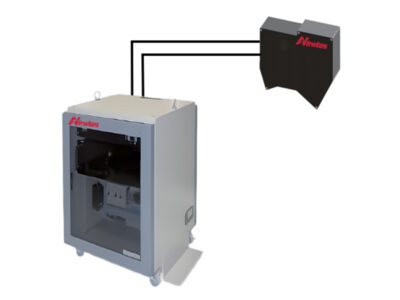

This is where the advanced variable speed flight welding technology developed by Newlas Company comes into play. This innovative solution has not only successfully addressed the high-speed computation issue but has also managed to ensure minimal distortion and precise welding positions, even during rapid acceleration and deceleration.

The application of this technology in the rotating tower battery welding production line is a testament to its effectiveness and efficiency. By utilizing variable speed flight welding, Newlas has been able to significantly improve the overall welding process, resulting in superior product quality and increased productivity.

The key to this success lies in the sophisticated algorithms and precise control systems employed by the Newlas technology. These systems enable real-time adjustments of the welding parameters, such as voltage and current, to compensate for the changes in speed and acceleration. As a result, the welding process remains stable and consistent, regardless of the speed variations.

Furthermore, the technology incorporates advanced sensor systems that continuously monitor and feedback important parameters, such as welding temperature and force, allowing for immediate adjustments to be made in case of any deviations from the desired parameters. This ensures that the welding quality is maintained at the highest possible standard.

The implementation of variable speed fly welding technology by Newlas Company has overcome the technical challenges associated with high-speed welding, ensuring accurate and distortion-free welds, even during acceleration and deceleration. This innovation has revolutionized the battery welding industry, setting a new benchmark for quality and productivity. With its continuous pursuit of excellence, Newlas Company is poised to lead the way in advanced welding technologies.

Author:Mac

mengxiaojun@newlas.com